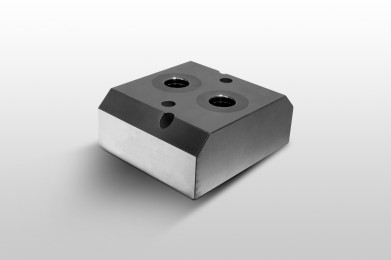

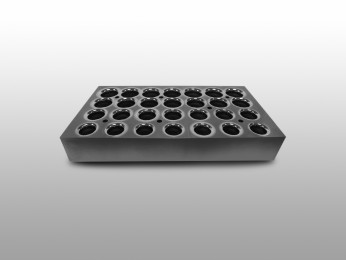

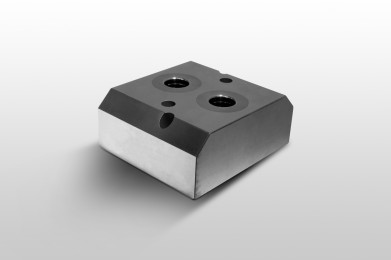

Sheet metal cold forming equipment

QP Mechanics si propone come costruttrice di vari accessori a disegno che compongono le singole stazioni di deformazione a freddo della lamiera.

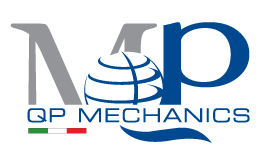

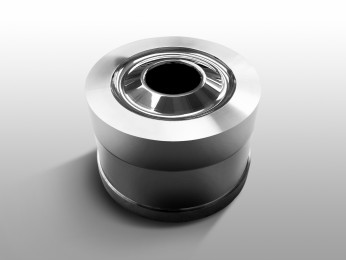

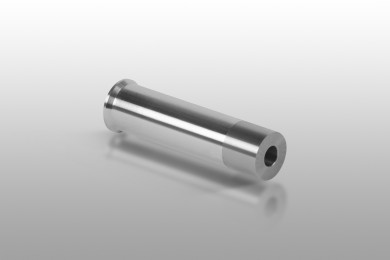

Dal pretranciato di partenza al pezzo finale la trasformazione della lamiera può avviene tramite imbutitura, stiramento, tranciatura o piegatura. I componenti presenti nelle singole stazioni sono svariati molti dei quali sono standard; normalmente invece le parti attive dello stampo e molti accessori a corredo sono da realizzare a disegno con specifiche ad HOC e materiali sempre più spinti a garantire le migliori performance per lo specifico caso. Qui entra in gioco il know-how di QP Mechanics realizzando proprio questi componenti con l'estrema cura dei dettagli che da sempre la contraddistingue. Alcuni esempi sono:

- Matrici

- porta matrici

- punzoni

- porta punzoni

- contropunzoni

- piastre

- premilamiera

- estrattori

- spine

In base alle necessità del cliente le attrezzature possono essere realizzate in acciaio, in carburo di tungsteno (widia) o altre leghe speciali.