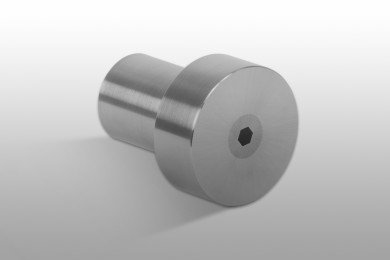

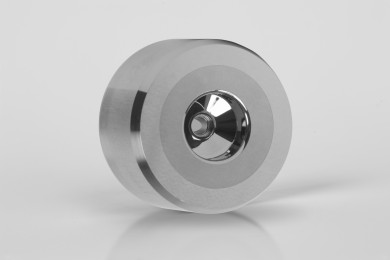

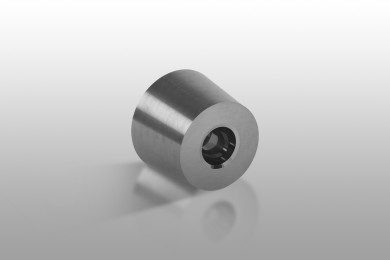

The die is fully made of tungsten carbide, which is a good choice in case of small sizes and/or with stresses that do not need a steel containment.

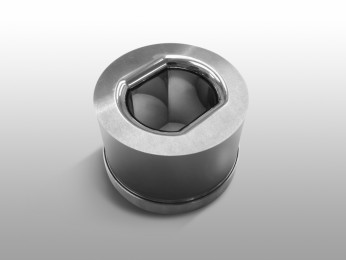

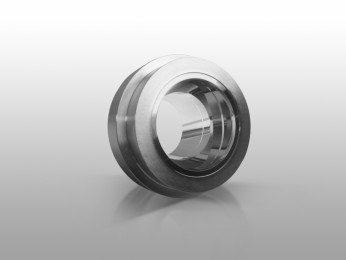

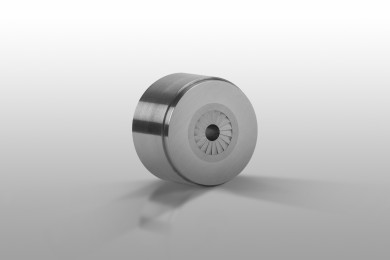

The die, made of hard metal, is assembled within a steel container. Depending on field of use, working conditions and stresses at stake, different assembly technologies will be used.

QP Mechanics has a sound experience in the working of steels for tools, in their various compositions and solutions offered by worldwide leading producers of steels for tools.

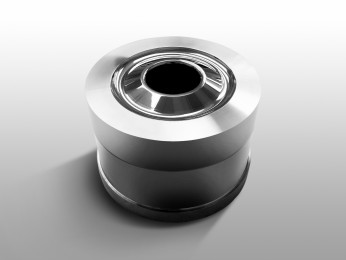

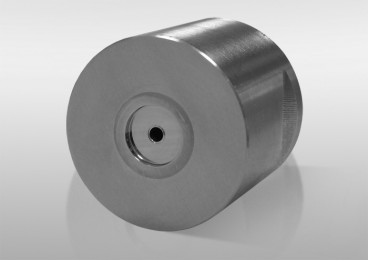

In many working conditions, the steel die is still the best choice.

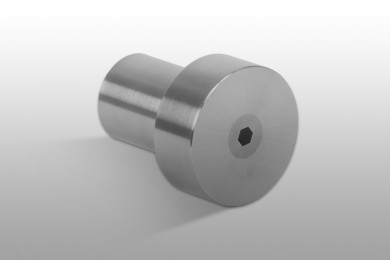

Tools with particular shapes, such as knurling or any shape of blind-end impressions.

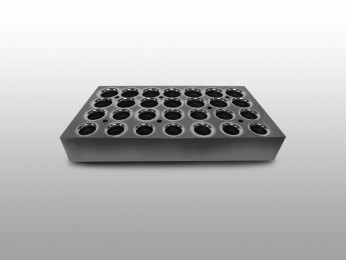

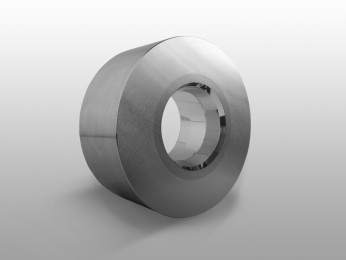

Dies made up of several components, usually with more than one insert, in Widia or not. In the simplest case, they are assembled axially, but in some special applications, the shoring is carried out in the radial direction.

Some examples are the sector hexagonal dies used in the field of hexagon headed bolts pressing, double-shoring dies and the ones called "Open", where the whole die is subdivided into the radial direction.